Packaging Vents

Your Questions. Our Answers

Frequently Asked Questions

What is porous PTFE?

PTFE (Polytetrafluoroethylene) is a synthetic fluoropolymer known for its hydrophobic properties. Porous PTFE membranes allow gas exchange through its microporous structure and repel water and other contaminants due to its natural hydrophobic properties.

How do PTFE membrane vents work?

PTFE membrane vents allow gases to pass through its porous structure while blocking liquids, helping to equalize pressure inside the packaging and prevent leakage.

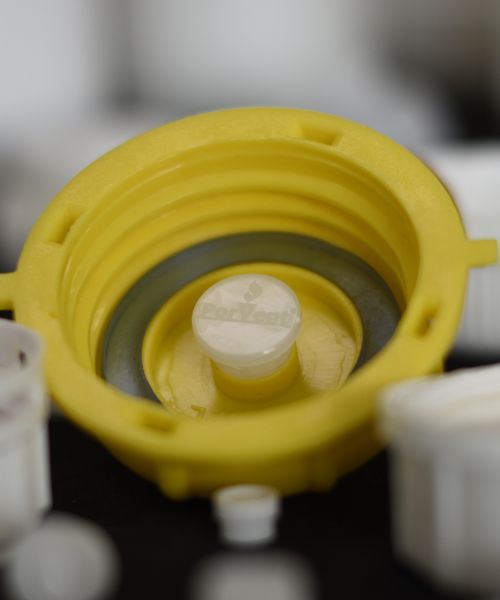

Which types of packaging vents incorporate PTFE membranes?

PTFE membranes are used to manufacture various types of packaging vents like vented push-fit plugs, vented inner plugs, vented liners, vented wads, vent caps and vented bungs.

Why does packaging need vents?

Packaging can fail due to various factors. Products generating or consuming gasses is one of the most common reasons for leakage and de-shaping if the container is completely sealed. Change in altitude also leads to pressure differential. Packaging vents help prevent de-shaping and leakage by enabling constant pressure equalization and blocking liquids/solids from getting in and out of the container.

What are the benefits of using PTFE membrane vents in packaging?

They provide excellent chemical resistance, prevent container deformation, and maintain product integrity by allowing air exchange without letting liquids in or out.

How do PTFE membrane vents contribute to product safety?

They help maintain product integrity by preventing contamination, leaks, and pressure build-up, ensuring the safety and quality of the packaged product by ensuring that the product is not exposed to contaminants and also ensuring that the user/handler is not exposed to any aggressive chemicals due to leakage.

Do PTFE membrane vents enable gas flow in both directions?

Yes, they allow bi-directional gas flow to balance internal and external pressure.

What is airflow, and why is it important?

Airflow indicates the vent’s performance in allowing air to pass through at a specific pressure difference, which is crucial for maintaining pressure balance.

What is the water entry pressure (WEP) of PTFE membrane vents?

WEP is a measure of the vent’s ability to resist water penetration. Higher WEP values indicate better performance in preventing liquid ingress.

Which industries commonly use PTFE membrane packaging vents?

These vents are widely used in the agrochemical, pesticides, bio-fertilizers, peroxides, acids, domestic & industrial cleaners, poultry & veterinary formulations, cosmetics, food supplements, construction & water treatment chemicals, and pharmaceuticals.

What are the benefits of using PTFE membrane vents in packaging?

They provide excellent chemical resistance, prevent container deformation, maintain product integrity by allowing air exchange without letting liquids in, and ensure leak-proof packaging.

Are PTFE membrane vents suitable for all types of packaging?

Yes, they can be integrated into various packaging types - bottles, jerrycans, drums and IBCs.

How durable are PTFE membrane vents?

PTFE membrane vents are highly durable and can withstand extreme temperatures, chemical exposure, and mechanical stress, ensuring long-term reliability.

What is the temperature range for PTFE membrane vents?

They typically operate effectively within a temperature range of -200°C to +260°C, making them suitable for various environmental conditions.

Can PTFE membrane vents be customized?

Yes, they can be tailored to meet specific requirements, including size, shape, and airflow characteristics, to fit different packaging designs.

Are PTFE membrane vents compatible with all chemicals?

PTFE is highly resistant to most industrial chemical packaging, but it’s always advisable to test the vent with your specific product to ensure compatibility. PorVent® can assist you with product compatibility tests.

How is the chemical compatibility of PTFE membrane vents tested?

Chemical compatibility is tested by exposing the vents to various industrial chemical packaging and observing any changes in performance or integrity.

What certifications do PTFE membrane vents typically have?

They often meet various industry standards such as ISO, FDA, and REACH compliance, depending on the application and region.

What are the common quality control measures for PTFE membrane vents?

Common measures include visual inspections, dimensional checks, and performance testing to ensure each vent meets the required specifications.

How is the performance of PTFE membrane vents ensured?

Performance is ensured through rigorous testing, including airflow, water entry pressure, and chemical resistance/compatibility tests, to meet industry standards.

Are there any special installation tools required for PTFE membrane vents?

Typically, no special tools are required, but proper installation techniques should be followed to ensure a secure fit to prevent leakage and provide venting.

What are the latest innovations in PTFE membrane vent technology?

Recent innovations include enhanced chemical resistance, improved airflow rates, and usage of better materials.

What kind of customer support is available for PTFE membrane vents?

PorVent® offers technical support, installation guidance, and troubleshooting assistance to ensure optimal performance.

Can I get a consultation for selecting the right PTFE membrane vent?

Yes, PorVent® provides consultation services to help you choose the best vent for your specific application needs.

How do PTFE membrane vents perform with aggressive chemicals?

PTFE membrane vents exhibit excellent resistance to aggressive industrial chemical packaging , including acids, bases, and solvents, making them suitable for harsh environments.

Can PTFE membrane vents be used with food and beverage packaging?

Yes, PTFE membrane vents can be used in food and beverage packaging, provided they meet food-grade standards and regulations.

Are PTFE membrane vents suitable for pharmaceutical applications?

They are ideal for pharmaceutical packaging due to their industrial chemical packaging resistance and ability to maintain sterile conditions.

How are PTFE membrane vents used in the cosmetics industry?

They are used in cosmetics packaging to prevent pressure build-up and protect the product from contamination and moisture.

What role do PTFE membrane vents play in agricultural packaging?

They help maintain the integrity of agricultural and industrial chemical packaging by allowing gas exchange while preventing leaks and contamination.

What precautions should be taken during the installation of PTFE membrane vents?

Ensure the vents are clean and free from contaminants and follow the manufacturer’s installation guidelines to avoid damage.